Problems with final product quality

What was the problem?

Defects in a film product!

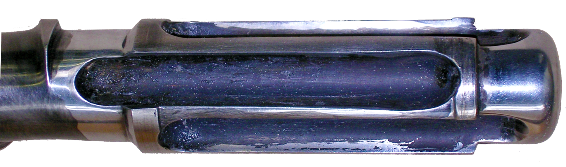

Defects were appearing in a 5-layer, coextruded, film product. Using microscopic analysis it was determined that the defects were occurring in one particular layer and upon further analysis, the defects were determined to be “gels” formed by degraded polymer. Based on the orientation and appearance of the defects, we advised the customer to examine the extruder screw for that layer. The following image shows the fluted mixing section of the screw.

The above image clearly shows the discoloration in the channels that typical results from polymer degradation (burning).

What was the root cause?

Poorly designed mixing element!

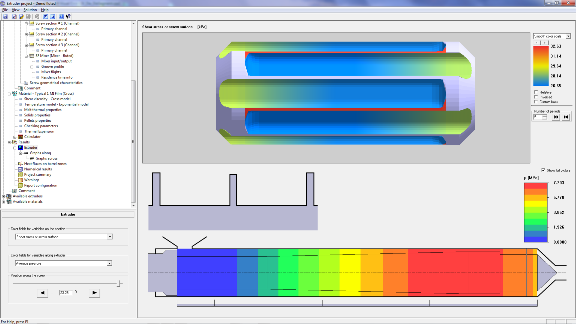

The following image shows the shear stress in the mixing section of the screw, as predicted by the VEL™ Extruder module simulation.

The analysis of the simulation results indicated that the fluted mixer was not designed correctly (for the particular polymer and process conditions) and thus, the mixer did not have adequate “self-cleaning” ability. Consequently, the polymer experienced a very long residence time in the mixer which led to the degradation(burning) and, ultimately, the defect that appeared on the final product.

How it was solved?

Improve the design of the fluted mixer!

Using the VEL™ Extruder module, the mixer design was improved/optimized, for the particular polymer and processing conditions, so that it had sufficient “self-cleaning” ability. Thus, the residence time on the surface was reduced and the degradation(burning) was eliminated which eliminated the defects in the film.

Bottom Line

Normally, it would have taken a long time to simply figure out where the problem was coming from. Using our experience, and simulation capabilities, we were quickly able to find the root cause of the problem. Once the source of the problem was understood, we were able to use the VEL™ Extruder module to, quickly and efficiently, find an optimized solution. Of course, optimizing the mixer (and screw) design, prior to manufacturing, could have avoided the problem (and the customer’s frustration) all together.